How Long Can You Hang a Deer in a Cooler

Information technology is always great being a tinkerer and someone else enlists your skills for their projects. Then you all the same get to tinker and brand things, only you can exercise it with "their" money. 😀 Life can't get better unless beer was free and didn't get warm. Such a thing happened this year as my buddy Kevin and I were talking about how it was so warm final year and nosotros didn't kill whatsoever deer early on because we self butcher. When it is warm yous have to pause the deer downwardly to buckets in the refrigerator fast and that is a lot of work just afterwards you tracked and dragged a deer out. Kevin said "Allow'southward build a cooler" and we started on pattern.

I am not going to get much into building the cooler frame every bit its just ii×4'due south on pressure treated landscape timbers with a rock floor built under his shed roof off his outbuilding. Kevin bought the 2×four'due south, I had nearly all the R13 insulation left over from my garage refinishing, nosotros got a costless exterior door from some other buddy and he got a deal on 1/4″ plywood on Facebook marketplace. So he bought a cheap used air conditioner and we built what yous see here with a pigsty for the air conditioner. If you demand to buy a new air conditioner this one is pretty cheap and 5000 BTU's.

Kevin saw the cost of the Coolbot controller at over $300 and texted me to assign my engineering resource to perform this task equally a more than cost constructive price range for an alternative. I did my enquiry and told him to buy the Inkbird controller ITC-1000 for $16 and to go the mounting box for nether $24 total for both. I told him I could make information technology work with it. This would control the compressor and when you switch the air conditioner on the fan runs 24/7 and the inkbird tell the compressor when to plow on and off. Below you can see the final setup and the inkbird is on the far right. Information technology and the air conditioner was all we started with. The Inkbird is fix to run until 40° and this was simply taken when the unit of measurement was off. The Argent box was added later for the failure you're near to read about.

And so initial tests seemed to piece of work and nosotros got the room down to 50° in a few hours. The whorl was icing but everything seemed to exist OK. So in the showtime of October my daughter shot a doe. Everyone is cheering, she got a deer and a real exam for the libation. Nosotros hang the deer, commencement the libation and take some beers and watch the libation. It looks good and Kevin goes out and checks it earlier bed. Its only down to high 40's and iced, simply its running. He wakes upwards Sunday and it tripped the GFI from existence over loaded, ice dripping or something and working as well hard and its 55° in the room. The deer is cold yet, but information technology is time to eat eggs fast and start butchering.

That was a failure because the freezing coil is straining the compressor. The air conditioner is not designed to be a cooler at 40°. So I had to figure out how to continue it from freezing upward the aforementioned fashion a Coolbot does. So I looked effectually and plant a Johnson Controls A19ABA-40C temperature sensor that would piece of work. Information technology would have closed contacts and open up on freeze so it could plough the compressor off when the coils froze upwardly. And then, when the compressor is off and resting the partially frozen coils are beingness defrosted by the running fan and still cooling the air in the libation.

This was prepare to nearly thirty° with virtually a viii° temperature differential. So when the coils reached 38° the compressor would plow back on.

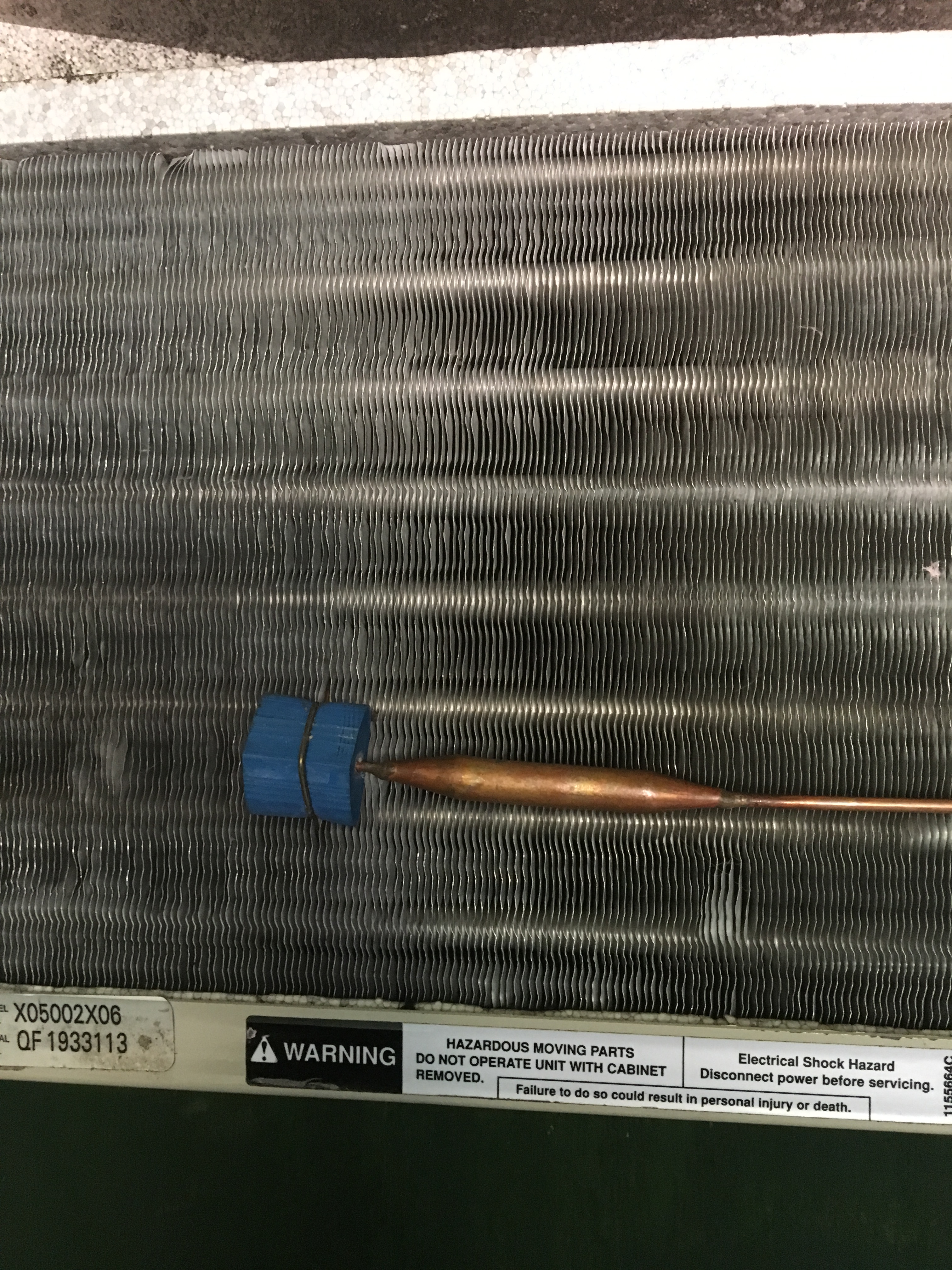

As y'all can see here I used the existing sensor mount and inserted our freeze sensor to lay flat on the coil. I had to bend the tip a few times to get it just correct to lay with light pressure against the coils.

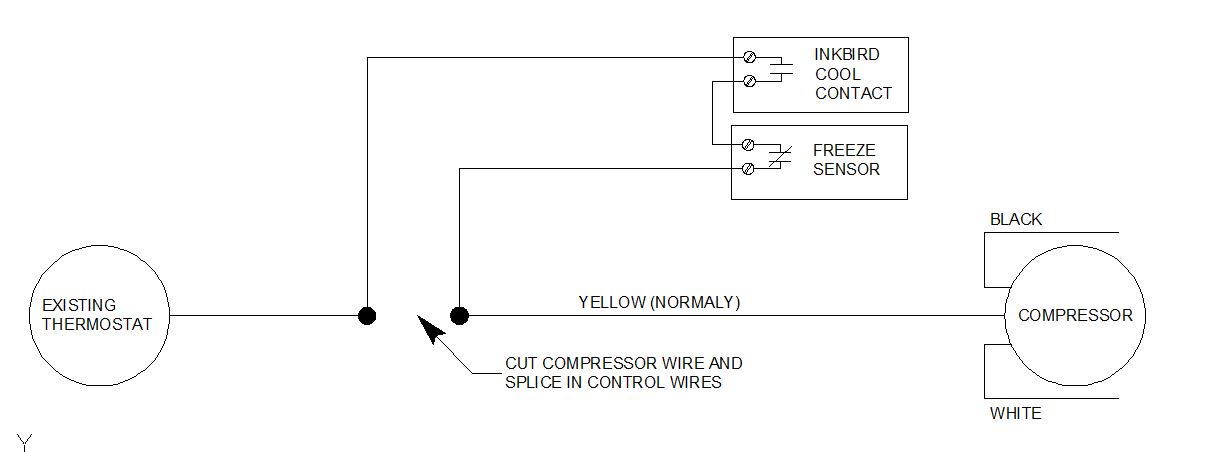

Hither is the wiring diagram. Most rut pumps and air atmospheric condition employ the standard colour of yellowish for the activation wire for the compressor or pump start. I cut the yellowish wire and inserted our controls instead of the existing command sensor.

As you can see when you offset it the Inkbird contact will close, or will already be closed because its warm in the cooler. When it gets to 40° this contact will open up and stop the compressor. When you lot first start it the units compressors works overtime trying to cool the room. When the coil freezes the compressor is running for null. The freeze sensor senses this and will open its contact letting the compressor have a break until the coils melt out.

Nosotros ran a test like this for over 24 hours and you could hear the compressor turning on and off occasionally as needed. Some water ice was on the coils, but information technology worked perfectly and we maintained 39° – forty° all the fourth dimension.

Now you besides could Redneck engineer a Coolbot on your own. The Coolbot sells for the cheapest I have seen for nigh $330 and I think we have less than that in the entire cooler.

Relish!

Rumble video added at present.

Source: https://archeryrob.wordpress.com/2017/11/07/deer-cooler-with-a-diy-coolbot-clone/

0 Response to "How Long Can You Hang a Deer in a Cooler"

Post a Comment